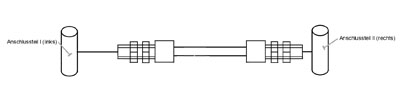

Bowden Cable with strain relief

Increasingly difficult demands on the functionality and safety of components and vehicles often put limits on conventional construction.

At ARC Reuter GmbH we would like to stand aside for you as a designer and developer of new modules with our long-term knowledge and experience and to design your Bowden cable safely and cost-effectively together with you.

What do we do for you?

- We accompany your project from the first idea and sketch to serial production at our partner

- We create drawings and data

- We build hand patterns and first samples

- We test Bowden cables on length, workmanship and longevity

- We manufacture the necessary serial devices suitable for the respective production

- We advise you Fachkundlich and neutral

- We work in partnership for the benefit of our customers

Ask us or arrange a consultation with us without obligation.

Bowden Cable Templates

You already know what type of custom Bowden cable you need and want it to be made by us? Here you will find technical templates in PDF format for your Bowden cable. Use these templates to order your custom Bowden cable with us.

You are also welcome to use the engineering drawings and blueprints for yourself. The templates are available for all different types of Bowden cables and ready to be filled in with you measurements.

Insight into our Manufeacturing Technologies

Zinc die Casting Plant for the production of high-strength compounds

Zinc die Casting is one of the most commonly used methods for producing a very tight connection with wire ropes. All shapes can be easily manufactured.

Zinc die Casting is one of the most commonly used methods for producing a very tight connection with wire ropes. All shapes can be easily manufactured.

Examples of some possibilities

CNC Park for the production of ropes and Bowden Cable Wraps

We manufacture turned parts for Bowden cables on the most modern CNC lathes. Our machine park comprises 3 CNC lathes.

Chiah Chyun CB 36 for the production of large series

Chiah Chyun CB 36 for the production of large series Chiah Chyun CB 36 by

Chiah Chyun CB 36 by Weiler CNC 120 for the production of single and small series up to 20mm diameter.

Weiler CNC 120 for the production of single and small series up to 20mm diameter. Serial turning parts produced on our CNC lathe Chiah Chyun CB 36

Serial turning parts produced on our CNC lathe Chiah Chyun CB 36 We produce many of the offered wire parts ourselves. Benefit from our extensive stock programme

We produce many of the offered wire parts ourselves. Benefit from our extensive stock programmePressing of Wires and Bowden Cable Wraps

Segment press for pressing the sleeves on Bowden cable wraps.

Segment press for pressing the sleeves on Bowden cable wraps. Eccentric press for the pressing of the wire.

Eccentric press for the pressing of the wire.Examples of compressed wire ends and wraps

Solder Bath

Solder bath for repairs and low-strength connections up to 50 kg traction.

Solder bath for repairs and low-strength connections up to 50 kg traction.

CNC Milling machines for the production of prototypes and small series

Kitamura CNC Center for the production of individual parts and small series for fastening of Bowden cable.

Kitamura CNC Center for the production of individual parts and small series for fastening of Bowden cable.Strength check of connections

In order to guarantee the safety of the Bowden cables, our products are regularly checked for the required strength. On request we will be happy to provide you with the values. Reference values are:

In order to guarantee the safety of the Bowden cables, our products are regularly checked for the required strength. On request we will be happy to provide you with the values. Reference values are:

- Soldering ca. 50 kg

- Presses on rope 1.5 mm approx. 120 kg

- Zinc die casting on rope 1.5 mm larger than rope break force

Who Invented it? Ernest Monnington Bowden

Patent 14402. The figures show the application of the invention, a bicycle rim break. A hand lever a pivoted on the handlebar is formed with an arm d ‘ of the brake, by a flexible c non-stretchable wire rope and free in a flexible hose b, of tightly wrapped wire, sliding. By this arrangement pressure on the lever a causes the Members B and C to start gliding and the brake is actuated. Excerpt from the patent specification 14402 from 14.05.1898

Patent 14402. The figures show the application of the invention, a bicycle rim break. A hand lever a pivoted on the handlebar is formed with an arm d ‘ of the brake, by a flexible c non-stretchable wire rope and free in a flexible hose b, of tightly wrapped wire, sliding. By this arrangement pressure on the lever a causes the Members B and C to start gliding and the brake is actuated. Excerpt from the patent specification 14402 from 14.05.1898